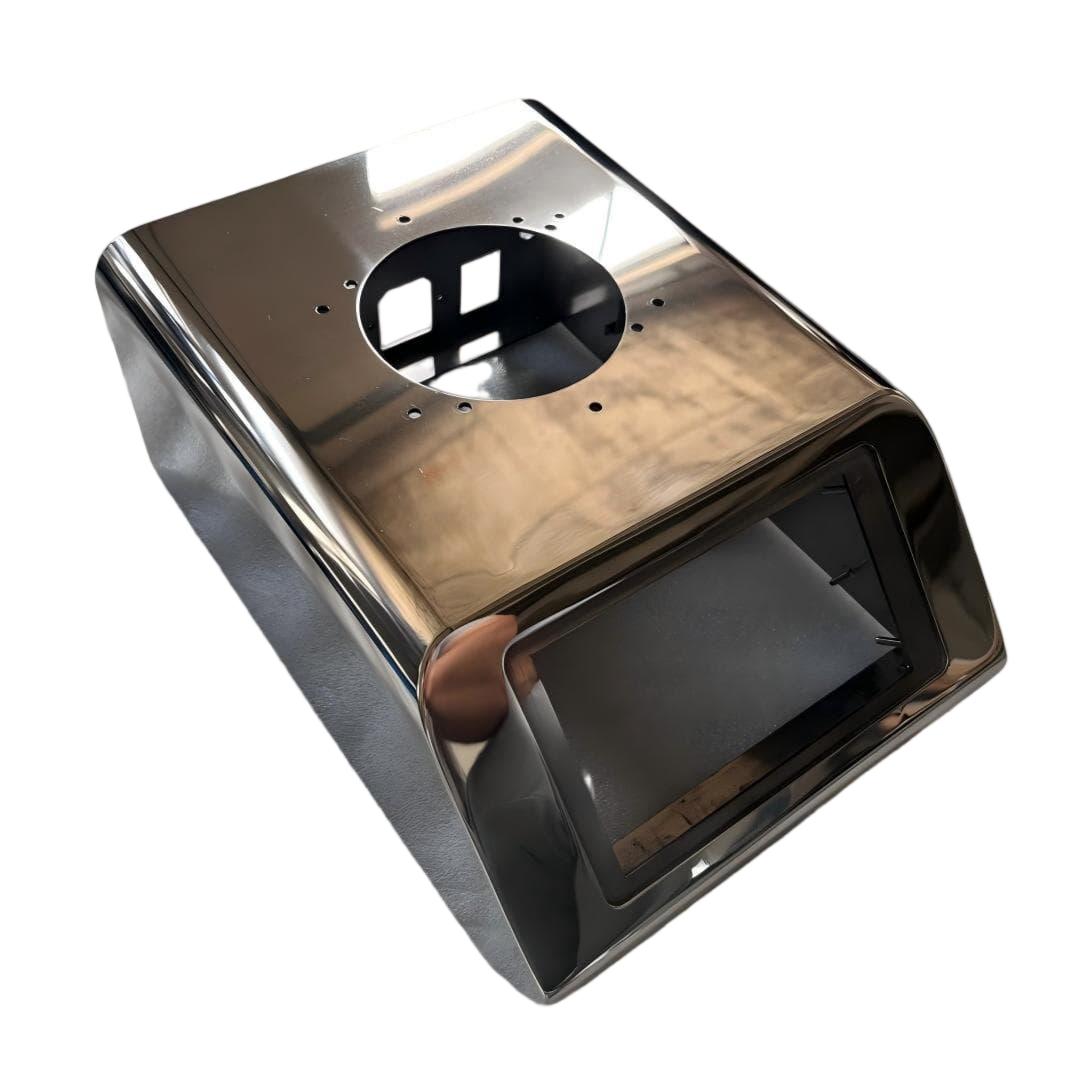

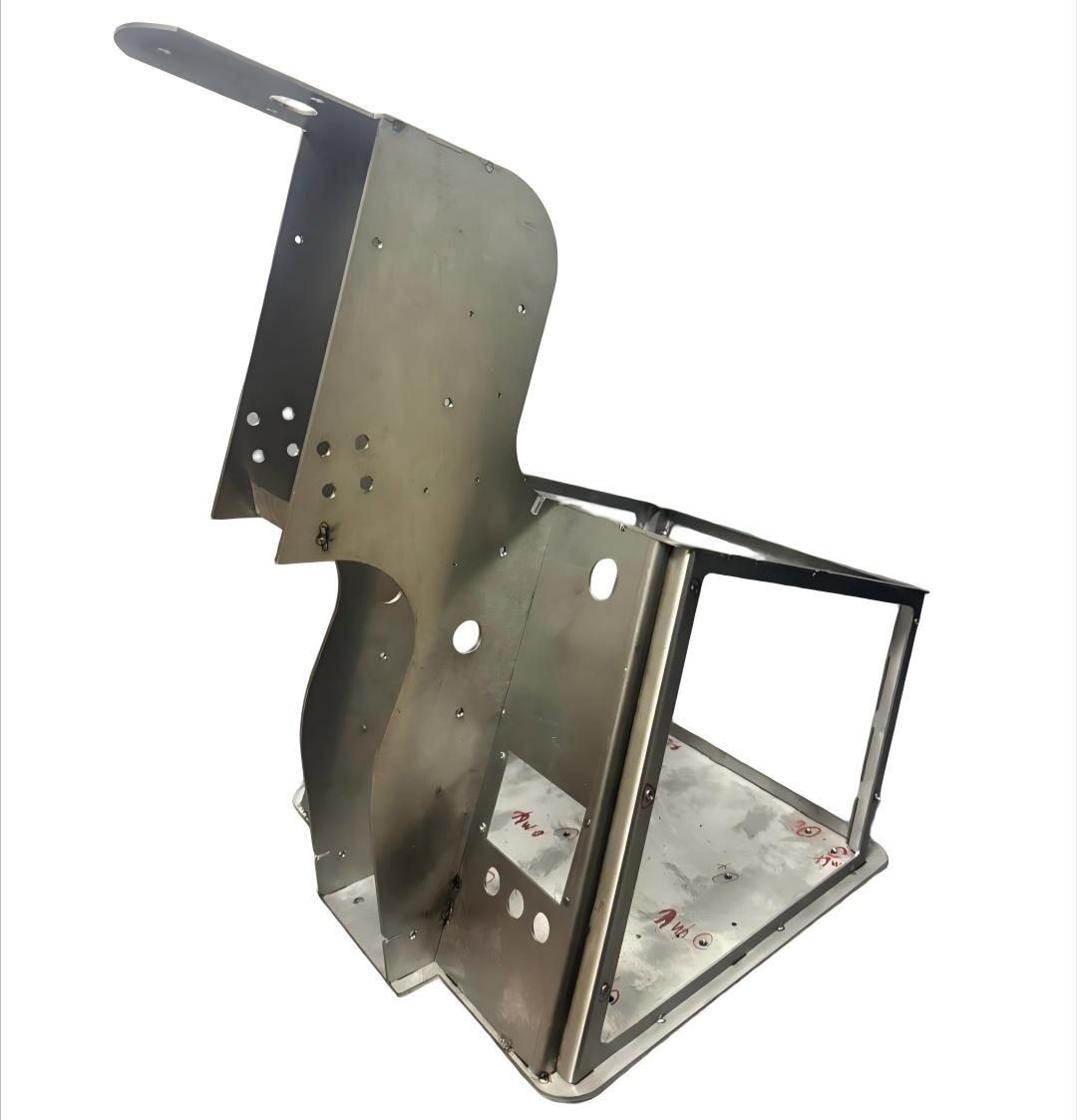

Sheet Metal Assembly

Our Comprehensive Sheet Metal Assembly Process

Our integrated sheet metal assembly process is designed to achieve maximum clarity. We first review the feasibility of the design engineering support and determine the foundation for your project. Next, we perform precision sheet metal fabrication to create components to exact specifications. Like: Cutting、Bending、Forming、Stamping. Finally, each sheet metal parts are connected through assembly techniques and assembled into a complete functional product in the final stage.

Advanced Sheet Metal Assembly Techniques

Expert Welding (MIG, TIG, & Spot)

Mechanical Fastening (Rivets, Bolts, Screws)

Adhesive Bonding

Hemming and Folding

Tab and Slot Assembly

Clinching (Press Joining)

Stud Insertion and PEM Fasteners

Modular and Electromechanical Assembly

Finishing, Powder Coating, Silk Screening, Plating

Industries We Serve with Custom Sheet Metal Assemblies

We have extensive experience providing high-quality custom sheet metal assemblies for aerospace, medical devices, automotive, and electronics. With our sheet metal assembly capabilities, you can quickly obtain a precisely assembled project, whether you need a complex enclosure or a precision structural component.

We have worked with the following industries:

Aerospace & Defense

Communication equipment

Medical

Robotics

Consumer Goods

Automotive

Security Equipment

Oil & Gas Equipment

Underwater Exploration

Frequently Asked Questions

What is your lead time for sheet metal assemblies?

Our standard lead time for most sheet metal assemblies is approximately 10-14 business days from the final approval of your design. However, this can vary based on part complexity, material availability, and finishing requirements. For urgent projects, we offer expedited services to accelerate your timeline. Please submit your project details for an accurate quote and a precise delivery schedule.

What types of assemblies can you complete?

We specialize in a broad spectrum of custom assemblies, from simple hardware insertion (PEMs, studs, standoffs) into brackets and enclosures to complex weldments and large electromechanical systems. Our team is equipped to manage multi-component projects that require the integration of machined parts, wiring, and diverse finishes, delivering a product that is ready for immediate use.

Besides sheet metal processing, what other manufacturing processes do you offer?

We operate as a comprehensive manufacturing partner. Beyond our core sheet metal capabilities, we offer extensive in-house services, including precision CNC Machining, Vacuum Casting, and a full range of Finishing, like powder coating and anodizing. This single-source solution streamlines your supply chain, reduces logistical complexity, and ensures perfect component compatibility from start to finish.

Why Choose Protofirster for Your Needs?

Your reliable partner for On-Time Sheet Metal Production, from design to delivery.

Our Advantages:

Fast Turnaround: 2 working days for urgent cases.

MOQ 1pc: Feasible for prototype and low volume to meet your requirements at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help provide DFM to improve your design and save on the budget.

One-stop service to achieve centralization and efficiency of the supply chain.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand.

Excellent quality and peace of mind - Expected results, guaranteed quality.

All CAD files are secure and confidential.