5-Axis CNC Machining Services

Manufacturing Capabilities

5-axis machining can perfectly process complex shapes, curves, multi-faceted features, and other challenges, and solves four major problems that traditional machining has difficulty dealing with.

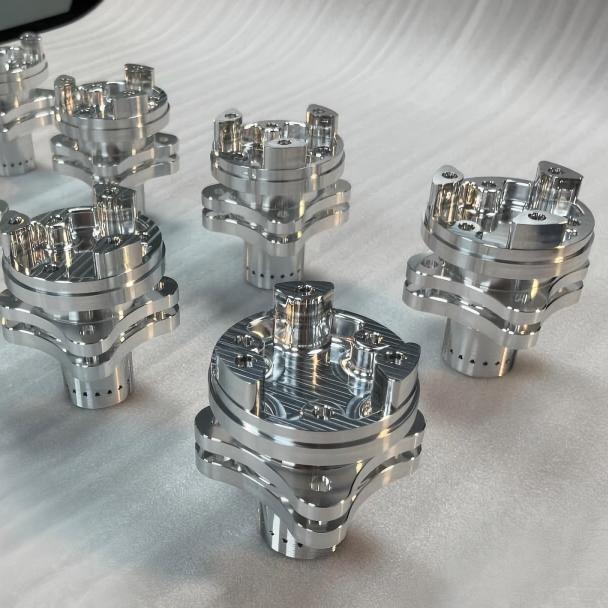

Inaccessible Features and Complex Geometry

By tilting the tool or rotating the part, the machine can easily reach almost any surface, allowing for incredibly complex designs in a single piece.

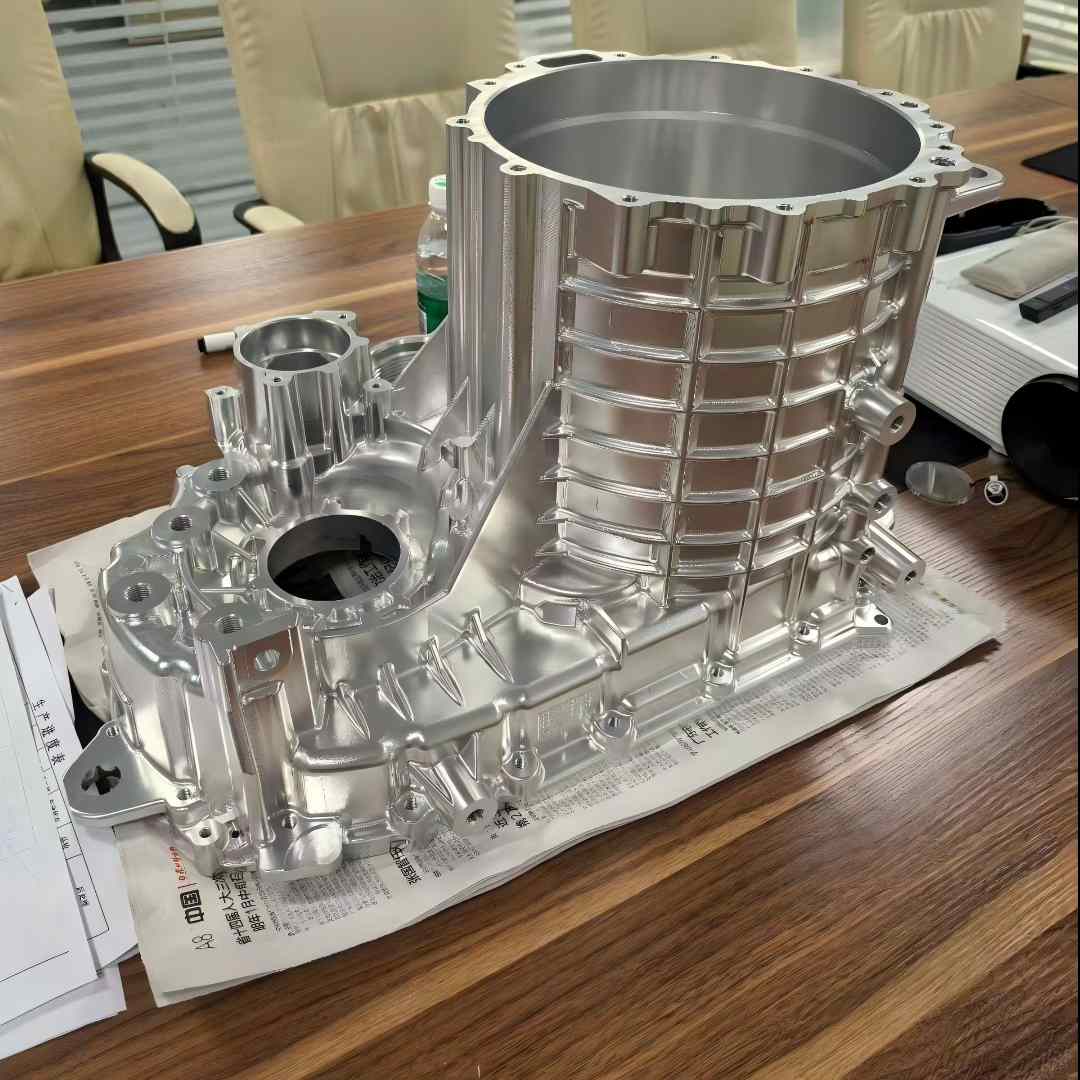

Wasted Time and Lower Accuracy from Multiple Setups

You can machine five sides of a part (top and all four sides) in a single setup. This is often called "Done-in-One" machining. It drastically reduces production time and increases accuracy because the part is never moved.

Poor Surface Finish on Curved Surfaces

It can keep the cutting tool perfectly perpendicular to the curved surface at all times. This creates a much smoother, higher-quality finish directly from the machine, reducing or eliminating the need for hand finishing.

Needing Long, Fragile Tools

The machine can tilt its head to get closer to the work area. This allows it to use shorter, more rigid tools, which are stronger and can cut faster and more aggressively, improving both speed and quality.

Industries We Served

Aerospace Components:

Turbine blades, impellers, wing brackets, and complex structural parts.

Automotive & Motorsport:

High-performance engine parts like cylinder heads, pistons, and impellers for turbochargers.

Industrial Robots:

Robot Joints & Housings, End-Effectors, Robot Skeletons.

Molds and Tooling:

Molds for creating plastic or metal parts.

Medical Devices:

Treatment equipment, health care, and genetic testing equipment.

Why Choose Protofirster for Your 5 Axis Machining Services?

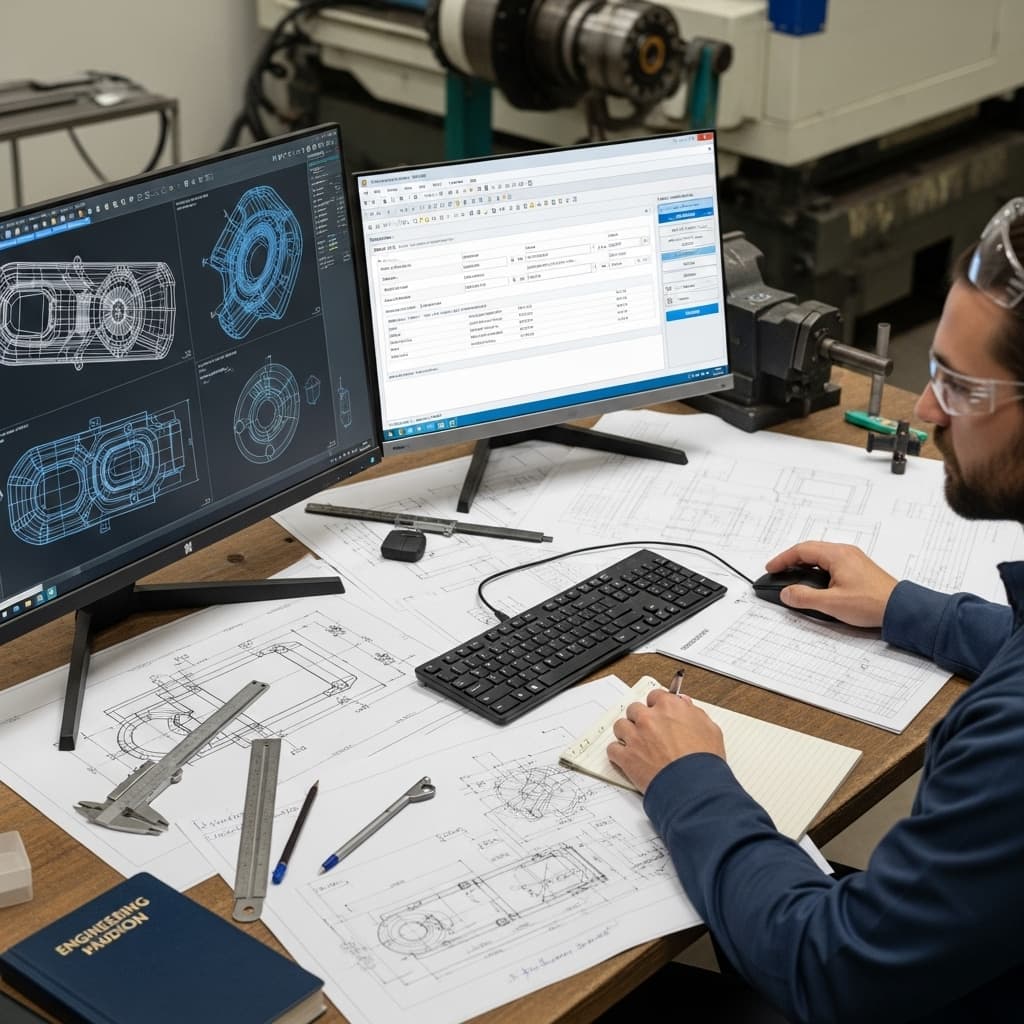

Advanced Equipment - Technology

Professional Team - Engineering & Operations

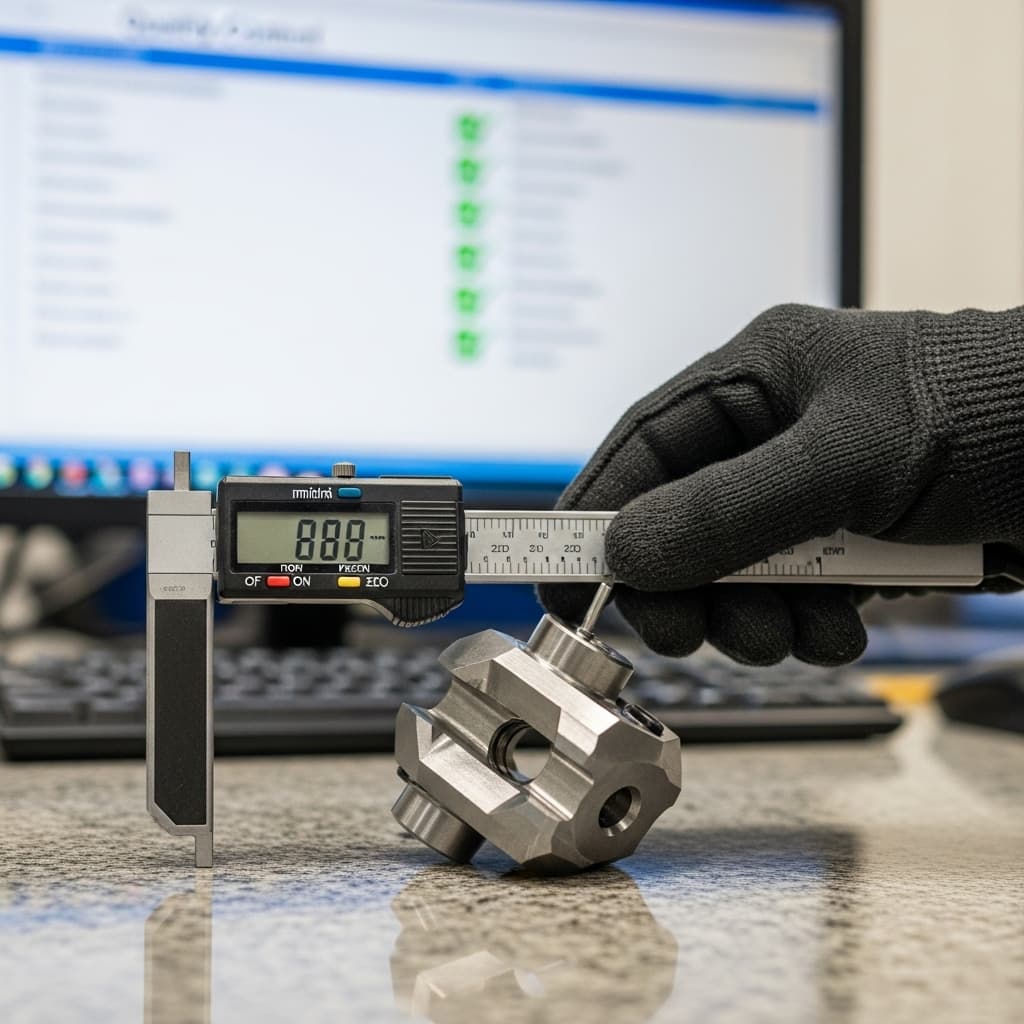

Commitment Assurance - Tolerances and Quality

Get a Fast - Competitive Quote for Your Project

![]()

Our Advantages:

Fast Turnaround: 2 working days for urgent cases

MOQ 1 Pcs: We support your requirements at any stage.

High Precision: The best we can do is ±0.025mm.

DFM Support: Our experienced engineers will help you verify and perfect the design.

Finishing Services: We provide anodizing, plating, sandblasting, brushing, and other processes to perfect your design.

Integrated Supply Chain: Easy to manage and improve time efficiency.

Your dedicated service consultant - tailor-made services.

All CAD files are secure and confidential.