Precision CNC Turning Services

What is CNC Turning?

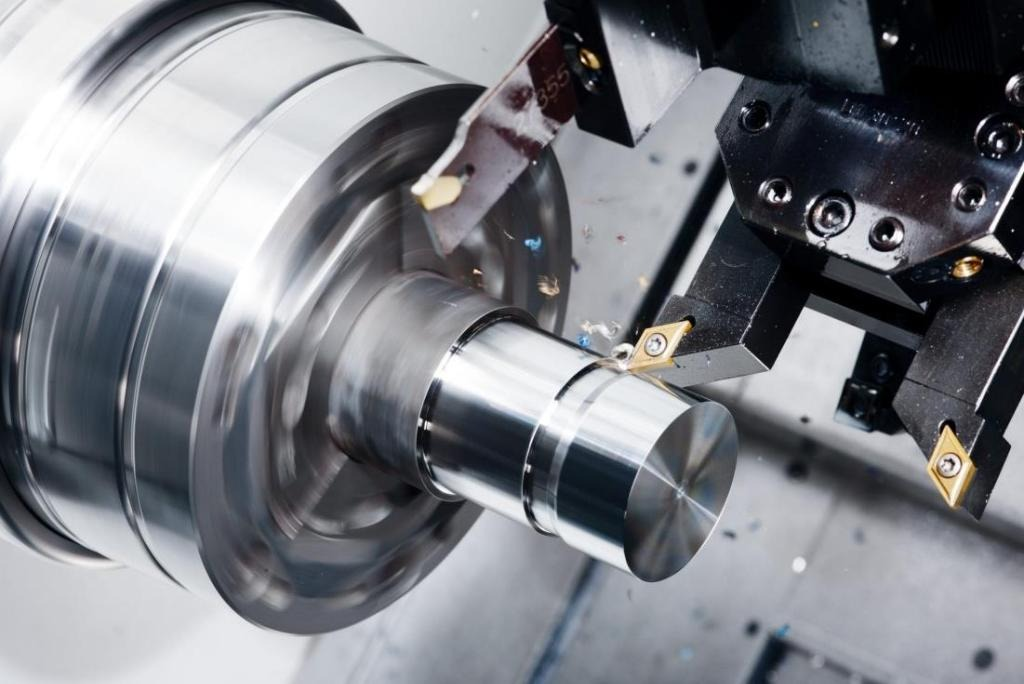

CNC turning is a machining process controlled by computer programs, used to manufacture cylindrical, but not limited to, metal or plastic precision parts.

How do we make a rough and solid metal rod into a component with a smooth surface and precise dimensions? Is it by hand grinding? No, we let the metal rod spin at high speed and then bring a sharp tool close to it. Then, a "brain" that absolutely obeys instructions controls the tool,

makes sure that each turning is precise and accurate, and can even manufacture complex threads and grooves.

The operation process can be done in three steps:

Get ready the materials and Workholding: First, a rod-shaped raw material (such as metal or plastic) is securely clamped in the lathe's chuck.

Setting Workpiece Rotation: The lathe drives the chuck and workpiece and then rotates at a set high speed and steadily.

Precision Cutting: At the same time, the cutting tool follows a CNC programming and moves precisely along the rotating workpiece,

cutting off excess parts from raw materials to create the final shape, including grooves, tapers, and threads.

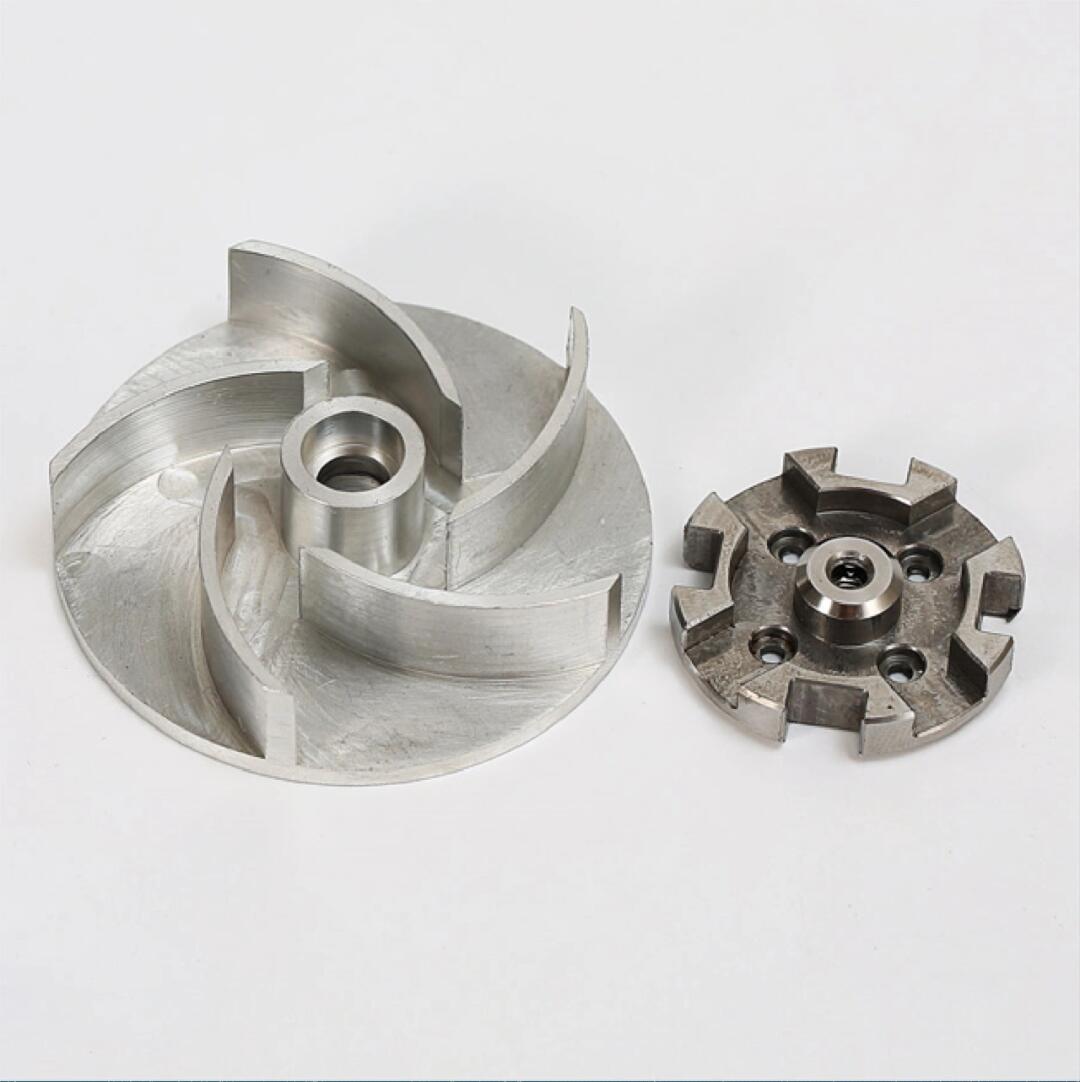

This process is manufacturing a variety of round, tapered, or cylindrical components, such as shafts, pins, bolts, and collars. It achieves extremely high accuracy and repeatability, and is a fundamental machining technology in modern precision manufacturing.

Advantages of the Turning Process:

High Precision: Turning can achieve highly precise shapes and dimensions.

Applicable Materials: including metals (such as steel, aluminum, and copper), plastics, and more.

High Flexibility: By changing different tools and adjusting processing parameters, various shapes can be produced.

Turning operations can be categorized into the following types based on specific machining needs:

External turning: used to produce the external surface of a workpiece.

Internal turning (or boring): used to produce cylindrical or tapered holes in a workpiece.

Facing: used to produce the end face of a workpiece to achieve a flat or specific shape.

Thread turning: used to cut internal and external threads into a workpiece.

Grooving and parting: used to cut grooves or completely part off a workpiece.

What industries use Precision Turned Parts?

With over 10 years of mechanical processing experience, we serve a wide range of industries with precision and expertise.

Medical

Robotics

Consumer Goods

Automotive

Aerospace

Defense

Marine

Security Equipment

Oil & Gas Equipment

Underwater Exploration

What materials are used in CNC Turning?

Selecting the processing material is a key step to the success of the project. There is no absolute "best" material, only the material that best suits the specific application requirements.

High-Performance Metals: From Aluminum to Titanium and Inconel

Aluminum Alloys: AL6061, AL7075, AL2024, AL5083, AL6063, AL1100, AL6082, AL7050

Stainless Steel: SS304, SS316L, SS321, SS310, SS416, SS420, SS440C, SS17-4PH, SS15-5PH

Carbon Steel & Alloy Steel: 1018, 1045, 4140, A36, Q235, 45#, D2, O1, A2, H13, S7, M2, SKD11, SKH9, P20, 718H, NAK80, C101, C110, C360, C464,

Bronze, Brass, Beryllium Copper, Ti-6Al-4V (Grade 5), Inconel 718, Inconel 625

In addition to metals, also excellent in processing various types of engineering plastics

Plastics Materials: ABS, POM (Delrin), PC, PA6 (Nylon 6), PA66 (Nylon 66), PMMA (Acrylic), PP, PE, PVC, PS, HDPE, LDPE, PEEK, PEI (Ultem), PSU, PPS,

PAI, PPA, LCP, PTFE (Teflon), PVDF, PCTFE, PPSU, PI (Polyimide), FEP, PFA, ETFE

Composite Materials: Carbon Fiber Sheet, Carbon Fiber Tube, Prepreg Carbon Fiber, Woven Carbon Fiber, Fiberglass, G10, FR4, Glass Fabric Laminate

Why Choose Protofirster for Your Precision Turning Needs?

We Commitment to Quality Control and Precision

Our Advantages:

Advanced Equipment & Multi-Axis CNC Turning Capabilities

Fast Turnaround: 2 working days for urgent cases

MOQ 1pc: Provide Solutions for Prototype & High-Volume Production to meet your requirements at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help to provide DFM to improve your design and save on the budget.

Secondary Finish: We provide anodizing, sandblasting, beadblasting, brushing, and many other processes of surface finish to perfect your design.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand

Excellent quality and peace of mind - Expected results, guaranteed quality

All CAD files are secure and confidential.

![1754494046212368.png Get In touch [640x480].png](/uploads/ueditor/image/20250806/1754494046212368.png)