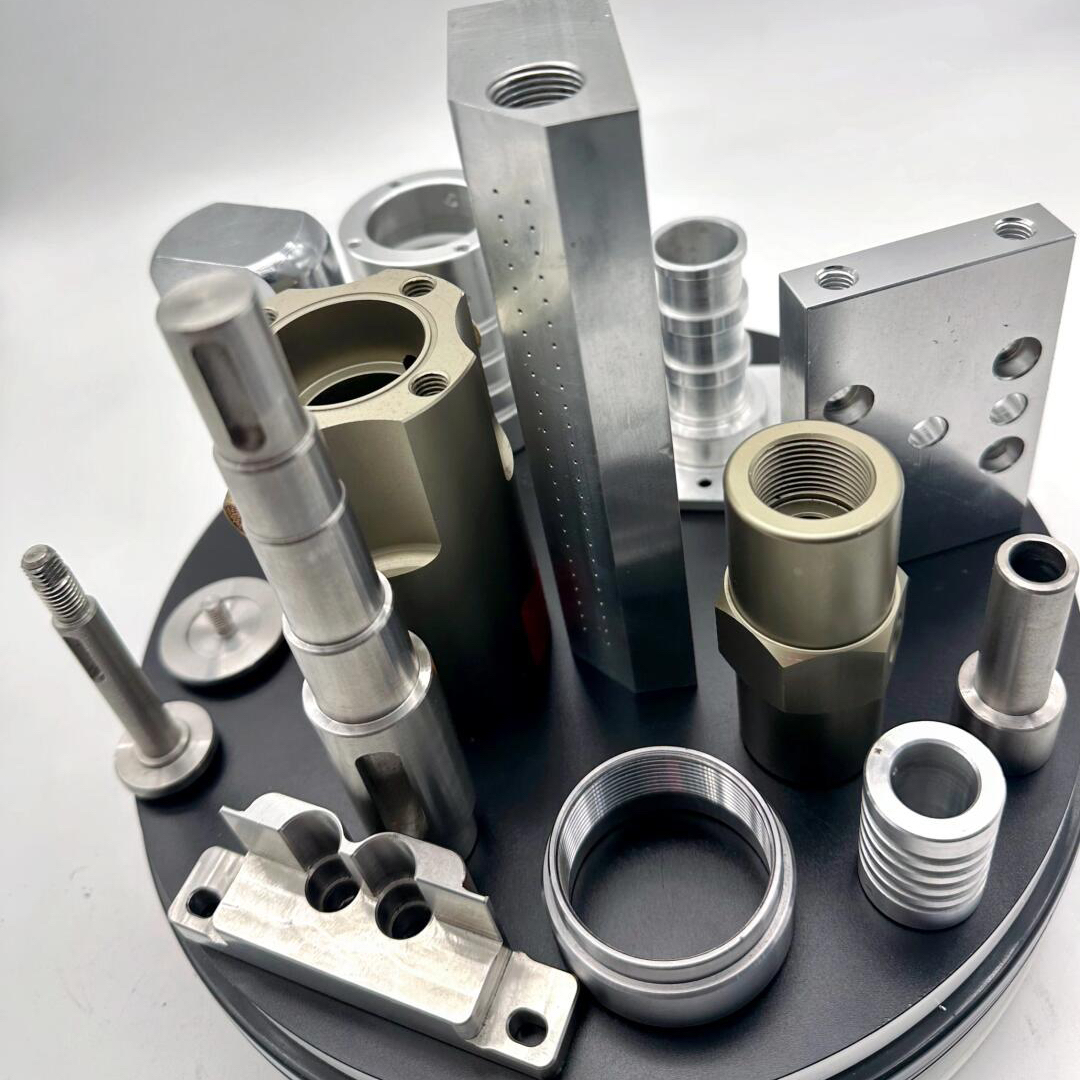

Online CNC Milling Precision Custom Parts Fast

What is CNC Milling?

CNC milling is a subtractive manufacturing technology in modern manufacturing. It not only seamlessly transforms digital designs (CAD/CAM) into high-precision physical objects but also revolutionizes production efficiency and product quality through its automation and high repeatability. From complex turbine blades in the aerospace industry to medical implants and precision housings for consumer electronics, CNC milling enables rapid prototyping, small-batch customization, and large-scale mass production of complex structural parts, making it a key driver of Industry 4.0 and smart manufacturing.

Our Key Types of CNC Milling: 3-Axis Machining and 5-Axis Machining

3-Axis Machining: The Economical, Standard Choice

This is the most basic form of CNC machining. The tool moves in three linear directions: X, Y, and Z. The workpiece remains stationary throughout the machining process.

Advantages:

Low Cost: Machine and programming costs are relatively minimal, and the technology is highly mature.

Versatile: Ideal for machining simple contours such as flat surfaces, holes, and grooves.

Suitable Projects:

Equipment panels, simple brackets, and bases

Signage lettering, mold cavities (internal shapes)

Most "square" parts

5-Axis Machining: Built for Extreme Complexity

This is the most advanced form of machining. It adds two rotary axes (typically A and B/C) to the three linear axes (X, Y, and Z). This allows the tool to approach the workpiece from any angle.

Advantages:

Extreme Complexity: Capable of producing parts with extremely complex geometries (such as turbine blades and human implants), including inclined surfaces and undercuts, in a single setup.

Higher Precision and Surface Finish: Enables the use of shorter, more rigid tools while maintaining the optimal cutting angle between the tool and the machined surface, resulting

in unparalleled accuracy and smoothness.

Highest Efficiency: Significantly reduces production cycle times, as complex parts do not require frequent repositioning and setup.

Suitable Projects:

Aerospace, Medical Devices, High-End Racing, etc.

Aircraft Turbine Blades, Engine Impellers

One-Piece Artwork or Concept Models

CNC Industry We Serve

With over 10 years of mechanical processing experience, we serve a wide range of industries with precision and expertise.

Medical

Robotics

Consumer Goods

Automotive

Aerospace

Defense

Marine

Security Equipment

Oil & Gas Equipment

Underwater Exploration

CNC Materials We Provide

Selecting the processing material is a key step to the success of the project. There is no absolute "best" material, only the material that best suits the specific application requirements.

High-Performance Metals: From Aluminum to Titanium and Inconel

Aluminum Alloys: AL6061, AL7075, AL2024, AL5083, AL6063, AL1100, AL6082, AL7050

Stainless Steel: SS304, SS316L, SS321, SS310, SS416, SS420, SS440C, SS17-4PH, SS15-5PH

Carbon Steel & Alloy Steel: 1018, 1045, 4140, A36, Q235, 45#, D2, O1, A2, H13, S7, M2, SKD11, SKH9, P20, 718H, NAK80, C101, C110, C360, C464,

Bronze, Brass, Beryllium Copper, Ti-6Al-4V (Grade 5), Inconel 718, Inconel 625

In addition to metals, also excellent in processing various types of engineering plastics

Plastics Materials: ABS, POM (Delrin), PC, PA6 (Nylon 6), PA66 (Nylon 66), PMMA (Acrylic), PP, PE, PVC, PS, HDPE, LDPE, PEEK, PEI (Ultem), PSU, PPS,

PAI, PPA, LCP, PTFE (Teflon), PVDF, PCTFE, PPSU, PI (Polyimide), FEP, PFA, ETFE

Composite Materials: Carbon Fiber Sheet, Carbon Fiber Tube, Prepreg Carbon Fiber, Woven Carbon Fiber, Fiberglass, G10, FR4, Glass Fabric Laminate

Why Choose Protofirster for Your CNC Milling Services Needs?

We provide exclusive, one-on-one 5-Axis CNC Machining Services consulting services, from design to delivery.

Our Advantages:

Fast Turnaround: 2 working days for urgent cases

MOQ 1pc: Feasible for prototype and low volume to meet your requirement at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help to provide DFM to improve your design and save on the budget.

Secondary Finish: We provide anodizing, sandblasting, beadblasting, brushing, and many other processes of surface finish to perfect your design.

One-stop service to achieve centralization and efficiency of the supply chain.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand

Excellent quality and peace of mind - Expected results, guaranteed quality

All CAD files are secure and confidential.

![1754494046212368.png Get In touch [640x480].png](/uploads/ueditor/image/20250806/1754494046212368.png)