CNC Machining Service

What is CNC Machining?

From Digital CAD Model to Physical Part

Automated Manufacturing: Computer Numerical Control (CNC) technology uses pre-programmed instructions to control machines.

Subtractive Process: Precisely cuts away and removes excess material from a solid block of raw material to form the desired part.

Digitally Driven: Directly transforms digital CAD models (e.g., STEP, IGES files) into high-precision physical components.

Customized Production: Capable of producing highly customized, complex-shaped parts, whether for prototypes or large-scale production.

Key Advantages: Precision, Speed, and Versatility

High Precision & Tolerances: Achieves extremely high dimensional accuracy and tight tolerance control, meeting the most demanding design requirements.

Fast Turnaround: Shortens production cycles, accelerating prototype development and time-to-market.

Wide Material Range: Can machine various metals and engineering plastics, offering great flexibility for product design.

Complex Geometries: Capable of handling intricate internal structures and external contours that are challenging with traditional methods.

Excellent Repeatability: Ensures consistency and stable quality for every part in batch production.

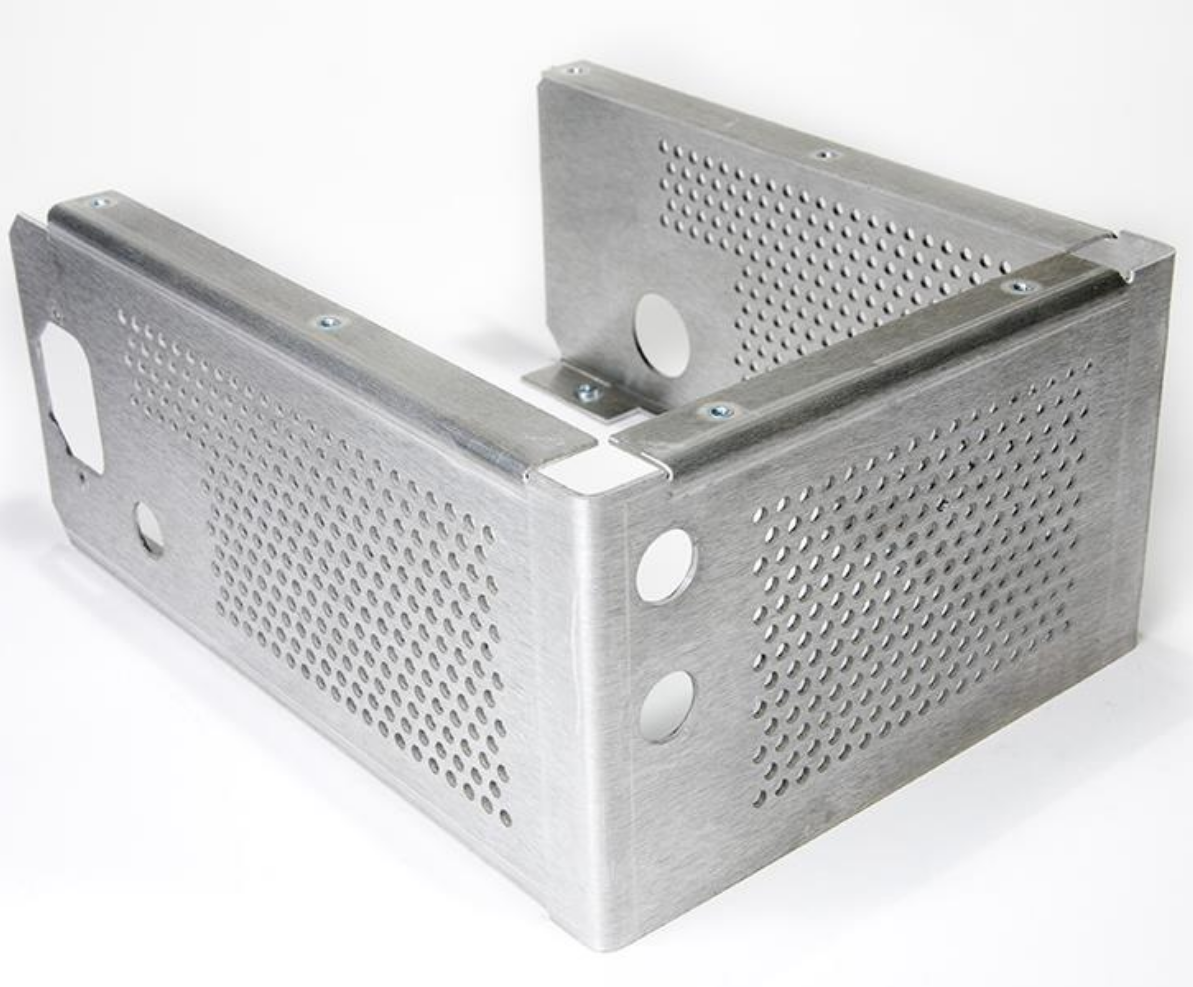

Our Comprehensive CNC Machining Services

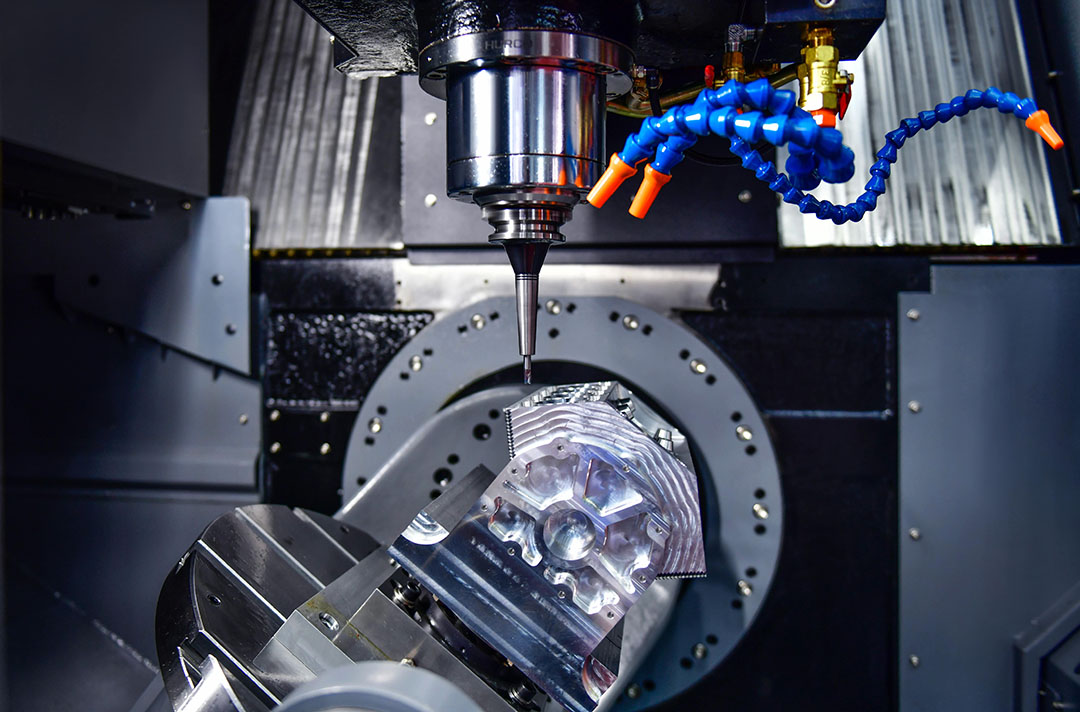

Protofirster provides a full range of precision CNC machining services, covering needs from simple to extremely complex parts, aiming to be your most trusted manufacturing partner. With nearly 100 advanced CNC machines (including high-end imported Japanese 5-axis machines), 24/7 production capabilities, and an experienced engineering team, we ensure your digital blueprints are efficiently transformed into high-precision, high-quality physical products. We excel at handling complex geometries, whether for rapid prototyping, low-volume production, or large-scale manufacturing, delivering with unparalleled speed and precision to help your products enter the market quickly and maintain a competitive edge.

CNC Milling Services for Complex Geometries

Multi-axis Machining: Uses a rotating multi-point cutting tool to remove material along X, Y, Z, and even more axes.

Suitable For: Producing parts with complex 3D shapes, pockets, slots, flat surfaces, and various features.

Extensive Applications: Provides high-precision milling solutions for everything from prototyping to mass production.

CNC Turning Services for Cylindrical Components

Turning Principle: The workpiece spins at high speed while a stationary cutting tool moves along the workpiece's axis to remove material.

Specialized In: Designed specifically for producing parts with circular or cylindrical features, such as shafts, pins, bushings, and connectors.

Efficient & Precise: Offers fast and high-precision cylindrical machining capabilities.

Advanced 5-Axis CNC Machining for Ultimate Precision

5-Axis Machining: The tool or workpiece can move simultaneously along five axes, allowing multi-sided machining in a single setup.

Manufacturing Complex Parts: Ideal for machining parts with free-form surfaces, complex angled features, and irregular geometries.

Reduced Setups: Significantly reduces the need for multiple setups, improving machining efficiency and surface finish.

Higher Accuracy: Eliminates cumulative errors, ensuring tighter tolerances and superior part quality.

Secondary Processing: Multi-faceted Surface Finish

Finish Services is a secondary process for improving a part's surface function, including appearance, corrosion resistance, wear resistance, and electrical conductivity. It includes: anodizing, sandblasting (bead blasting), brushing, polishing, electroplating, passivation, painting (powder coating), heat treatment, laser marking, and chemical plating.

While there are many options, not all are suitable for all materials. For example, anodizing is good for used aluminum alloys, while passivation is used for stainless steel.

The choice depends on the part's application, material, design requirements, cost, and specific appearance and performance requirements. Compatibility issues may exist between different surface treatments, so selection requires a case-by-case approach.

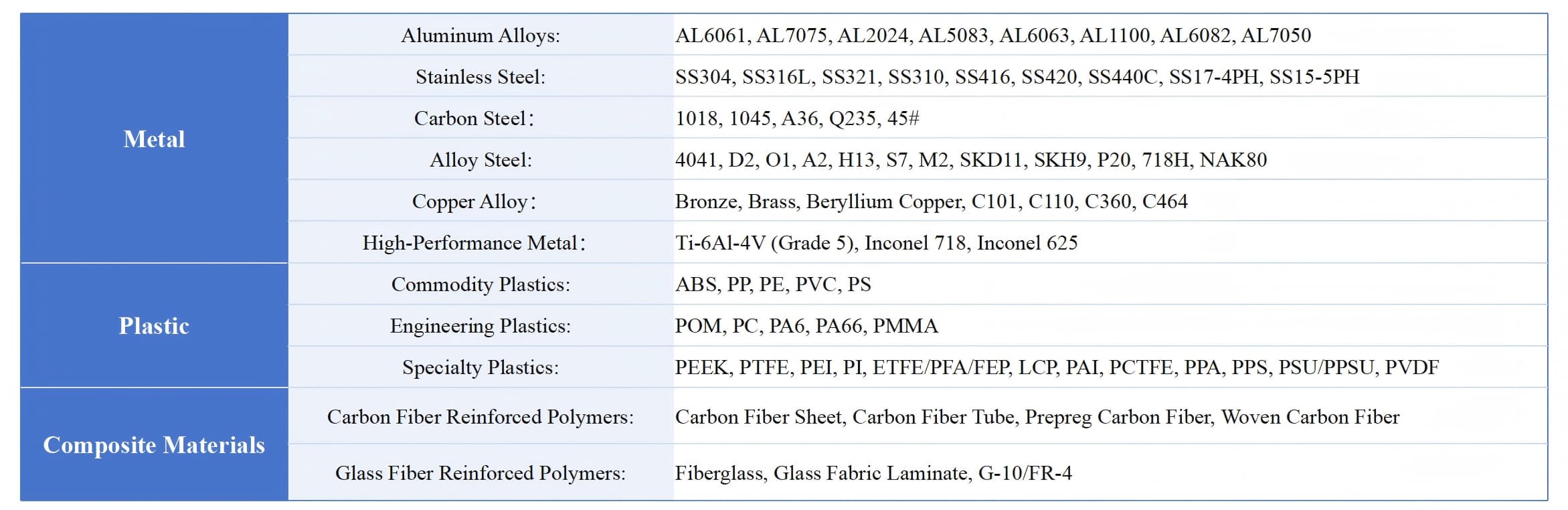

What materials can be CNC machined?

If we don't have the material you want, please contact us by email.

How Can I Get My Parts?

1. Send Us Inquiry ->

Directly send your file or send your project message through the quote page. All files are under NDA support.

2. Quote & DFM ->

Within 8 hours, we’ll send back the Design For Manufacture analysis and real-time quote.

3. Production & QC ->

Once the order is confirmed, we’ll start the manufacturing process with your CAD. Our quality control is not just a final step, but a process integrated throughout production.

4. Global Delivery->

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

We are committed to solving your problem

Our Advantages:

Advanced Equipment & Multi-Axis CNC Capabilities.

Fast Turnaround: 2 working days for urgent cases.

MOQ 1pc: Provide Solutions for Prototype & High-Volume Production to meet your requirements at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help provide DFM to improve your design and save on the budget.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services.

Easy to understand and communicate with us in a language you understand.

Excellent quality and peace of mind - Expected results, guaranteed quality.

All CAD files are secure and confidential.