Rapid Prototyping Services

What is Rapid Prototyping and its Benefits?

Rapid prototyping is a collection of technologies used to quickly transform a digital idea into a real model. It serves as a critical bridge in the product development process of Industry 4.0, turning CAD Design into real objects.

From Design to Concept Model

The process begins with a digital blueprint, a CAD Design file. Advanced manufacturing techniques like CNC and Additive Manufacturing are then used to build this virtual design—either layer by layer or through subtractive cutting—into a physical part you can touch and feel. This leap from virtual to reality fundamentally changes how designers and engineers interact with their work, allowing them to literally hold their ideas in their hands.

The Key Goal: Validating Design Before Production

However, the core objective of rapid prototyping extends far beyond simply creating a model. Its true value lies in "pre-production validation." By creating a functional proof of concept model, a team can test the look, feel, and function of a design before investing in expensive tooling and full-scale manufacturing. This makes it possible to identify and fix design flaws at an early stage, dramatically reducing development risks and downstream costs.

Core Benefits of the Rapid Prototyping Process

1. Accelerate Time-to-Market and Gain a Competitive Edge

By manufacturing concept model in days, you can quickly conduct product testing, design iteration, and finalize. Shortens the product development and enables you to beat competitors' time to market.

2. Reduce Development Costs and Minimize Financial Risk

By identifying design flaws, ergonomic issues, or assembly problems with a low-cost prototype, you can make corrections before committing to expensive production molds.

3. Improve Product Design with Tangible Feedback

A physical prototype provides invaluable, tangible feedback that digital models cannot. Essential for refining usability, perfecting functionality, and creating a final product that truly resonates with its end-users.

Our Rapid Prototyping Technologies

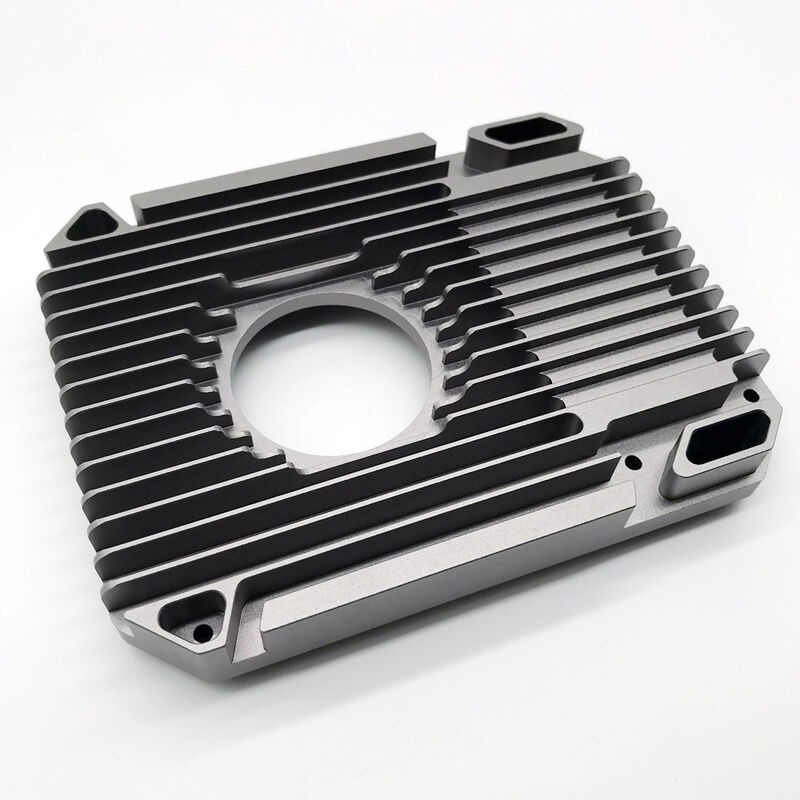

CNC Machining - For high-precision parts in metal and plastic

This is a common subtractive manufacturing process that uses high-speed milling, drilling, turning, and other methods to remove excess material from a solid block of material to create a prototype. Its advantage lies in its ability to precisely produce complex parts in a variety of materials with high precision and excellent surface quality. It is also material-neutral, allowing you to choose the appropriate metal or ABS based on your design requirements.

Sheet Metal Fabrication- For durable enclosures, brackets, and panels

This process involves transforming or joining thin metal sheets through a series of processing steps to create parts of the desired shape and size. For example, shearing, punching, bending, laser cutting, welding, riveting, forming, Surface Finishing, etc. They are ideal for creating strong yet lightweight structures. A very excellent way to test the form and fit of an enclosure before investing in expensive tooling.

Vacuum Casting - A key component of the Low-volume production runs

Vacuum casting creates high-fidelity prototypes with an excellent surface finish. Advantage lies in its ability to achieve cost-effectiveness of low-volume production, functional testing, and marketing samples. Delivering exceptional results without expensive tooling. The key point is to help you achieve greater price competitiveness.

Surface Finishing - Improve the functionality & appearance of the substrate

Surface Finishing enhances a material's surface to improve durability, corrosion resistance, & aesthetics. This essential process is used across industries like automotive, aerospace, & electronics to boost product performance, protect components, and extend lifespan.

Industries That Rely on Rapid Prototyping

With over 10 years of mechanical processing experience, we serve a wide range of industries with precision and expertise.

Medical

Robotics

Consumer Goods

Automotive

Aerospace

Defense

Marine

Security Equipment

Oil & Gas Equipment

Underwater Exploration

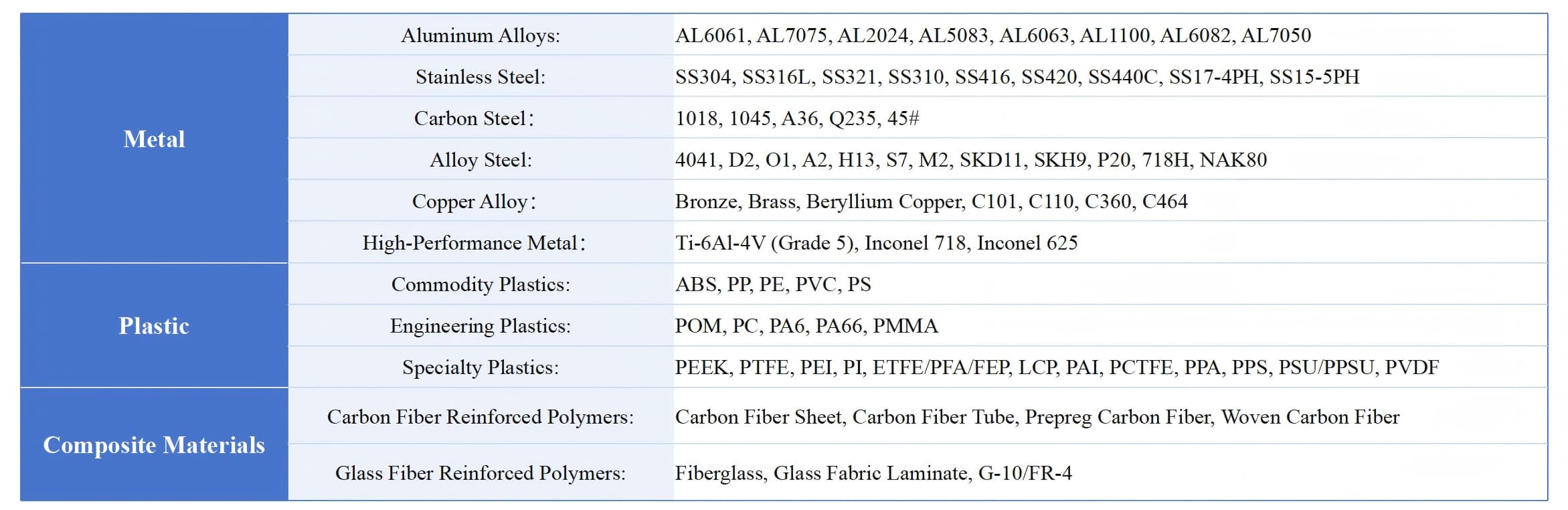

Materials We Provide

Selecting the processing material is a key step to the success of the project. There is no absolute "best" material, only the material that best suits the specific application requirements.

Why Choose Protofirster for Your Rapid Prototyping Services Needs?

We provide exclusive, one-on-one rapid prototyping consulting services, from design to delivery.

Our Advantages:

Fast Turnaround: 2 working days for urgent cases.

MOQ 1pc: Feasible for prototype and low volume to meet your requirements at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help provide DFM to improve your design and save on the budget.

One-stop service to achieve centralization and efficiency of the supply chain.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand.

Excellent quality and peace of mind - Expected results, guaranteed quality.

All CAD files are secure and confidential.