Rapid Prototyping

What is Rapid Prototyping?

Can you believe a brand new product concept can go from a paper idea to a tangible prototype in just a few days, or even a day? That's the incredible power of Rapid Prototyping technology! It's no longer a distant future, but a disruptive "blitzkrieg" strategy for product development today. Simply put, Rapid Prototyping is a system that enables innovation and design iteration at breakneck speed. At its core, it is to use technologies such as additive manufacturing and subtractive manufacturing to quickly and accurately turn your drawings into physical objects. Core meaning is: "Have a problem? Test it now, fix it fast!"

The Right Technology for Your Project, Managed by Me

Now that you understand the core benefits of rapid prototyping, you might ask: Which rapid prototyping process meets my needs? We offer the following three core manufacturing technologies:

CNC Machining - For high-precision parts in metal and plastic

This is a common subtractive manufacturing process that uses high-speed cutting, drilling, milling, and other methods to remove excess material from a solid block of material to create a prototype. Its advantage lies in its ability to rapidly produce complex parts in a variety of materials with high precision and excellent surface quality. It is suitable for functional prototypes and low-volume production. It is also material-neutral, allowing you to choose the appropriate metal or ABS based on your design requirements.

Sheet Metal Fabrication - For durable enclosures, brackets, and panels

This process involves transforming or joining thin metal sheets through a series of processing steps to create parts of the desired shape and size. For example, shearing, punching, bending, laser cutting, welding, riveting, forming, surface treatment, etc. They are ideal for creating strong yet lightweight structures. Mush excellent way to test the form and fit of an enclosure before investing in expensive tooling.

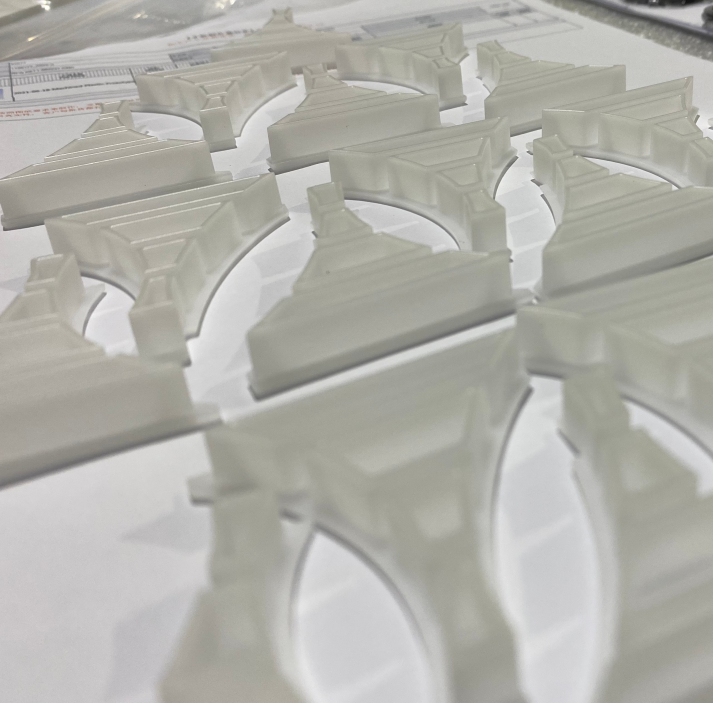

Injection Molding - A Key Component of the Small Batch Replication Stage

Injection molding's core advantage lies in its ability to deliver high efficiency and cost-effectiveness. Through efficient rapid tooling and small batch replication, it significantly improves the efficiency and speed of the entire product development process, making it an indispensable component of rapid prototyping solutions.

Industry We Serve

With over 10 years of mechanical processing experience, we serve a wide range of industries with precision and expertise.

Medical

Robotics

Consumer Goods

Automotive

Aerospace

Defense

Marine

Security Equipment

Oil & Gas Equipment

Underwater Exploration

Materials We Provide

Selecting the processing material is a key step to the success of the project. There is no absolute "best" material, only the material that best suits the specific requirements.

High-Performance Metals: From Aluminum to Titanium and Inconel

Aluminum Alloys: AL6061, AL7075, AL2024, AL5083, AL6063, AL1100, AL6082, AL7050

Stainless Steel: SS304, SS316L, SS321, SS310, SS416, SS420, SS440C, SS17-4PH, SS15-5PH

Carbon Steel & Alloy Steel: 1018, 1045, 4140, A36, Q235, 45#, D2, O1, A2, H13, S7, M2, SKD11, SKH9, P20, 718H, NAK80, C101, C110, C360, C464,

Bronze, Brass, Beryllium Copper, Ti-6Al-4V (Grade 5), Inconel 718, Inconel 625

In addition to metals, Rapid Prototyping is also excellent in processing various types of engineering plastics

Plastics Materials: ABS, POM (Delrin), PC, PA6 (Nylon 6), PA66 (Nylon 66), PMMA (Acrylic), PP, PE, PVC, PS, HDPE, LDPE, PEEK, PEI (Ultem), PSU, PPS,

PAI, PPA, LCP, PTFE (Teflon), PVDF, PCTFE, PPSU, PI (Polyimide), PTFE, FEP, PFA, ETFE

Composite Materials: Carbon Fiber Sheet, Carbon Fiber Tube, Prepreg Carbon Fiber, Woven Carbon Fiber, Fiberglass, G10, FR4, Glass Fabric Laminate

Why Choose Protofirst for Your Rapid Prototyping Services Needs?

We provide exclusive, one-on-one rapid prototyping consulting services, from design to delivery.

Our Advantages:

Fast Turnaround: 2 working days for urgent cases

MOQ 1pc: Feasible for prototype and low volume to meet your requirement at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help to provide DFM to improve your design and save on the budget.

Secondary Finish: We provide anodizing, sandblasting, beadblasting, brushing, and many other processes of surface finish to perfect your design.

One-stop service to achieve centralization and efficiency of the supply chain.

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand

Excellent quality and peace of mind - Expected results, guaranteed quality

All CAD files are secure and confidential.

![1754469881536655.png Get In touch [640x480].png](/uploads/ueditor/image/20250806/1754469881536655.png)