5-Axis CNC Machining Services

What is 5-Axis CNC Machining Technology?

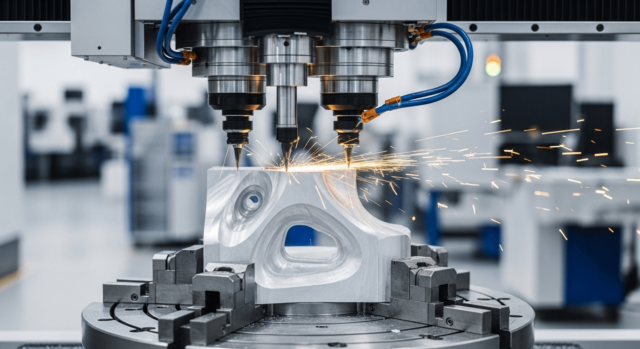

It is an advanced subtractive process different from the traditional 3-axis(which only controls the X, Y, and Z linear axes) processing technology. 5-Axis technology adds two additional rotary axes (usually A, B, or C). That uses high-speed cutting can move the cutting tool or part in five different axes at the same time, enabling the manufacturing of complex parts

It is this technology that enables innovative designs in aerospace, medical devices, mold manufacturing, and automotive. Also, an ideal choice for industries that have strict requirements on precision and complexity.

Whether it is 1 piece or 5 pieces, we manufacture the parts you need with the same precision and without tolerance.

Key Benefits of Choosing 5 Axis CNC Machining

Manufacturing complex, multi-faceted, and precise parts:

With its ability to move the tool or workpiece in 5 dimensions at the same time, it is possible to "carve" these amazingly complex parts in one time, making designs that were almost impossible to achieve in the past a reality.

Advanced machining precision and surface finish:

The cutting tool can always approach the workpiece surface at the optimal angle, reducing the cumulative error caused by clamping and repositioning, making the surface quality of the final product smooth and delicate, and improving the product qualification rate.

Improving production efficiency and shortening manufacturing cycles:

The most direct efficiency improvement lies in "completion of multi-surface processing in one clamping." Shortens overall processing time, allowing your products to be put on the market faster.

Effectively reducing unit production costs and scrap rates:

Increased efficiency translates directly into lower costs. Reducing multiple setups means significant savings in manual operation time, while also reducing the potential for human error and part scrap caused by repeated setups.

CNC Industry We Serve

With over 10 years of mechanical processing experience, we serve a wide range of industries with precision and expertise.

Medical

Robotics

Consumer Goods

Automotive

Aerospace

Defense

Marine

Security Equipment

Oil & Gas Equipment

Underwater Exploration

CNC Materials We Provide

High-Performance Metals: From Aluminum to Titanium and Inconel

Aluminum Alloys: AL6061, AL7075, AL2024, AL5083, AL6063, AL1100, AL6082, AL7050

Stainless Steel: SS304, SS316L, SS321, SS310, SS416, SS420, SS440C, SS17-4PH, SS15-5PH

Carbon Steel & Alloy Steel: 1018, 1045, 4140, A36, Q235, 45#, D2, O1, A2, H13, S7, M2, SKD11, SKH9, P20, 718H, NAK80, C101, C110, C360, C464,

Bronze, Brass, Beryllium Copper, Ti-6Al-4V (Grade 5), Inconel 718, Inconel 625

In addition to metals, 5-axis machining is also excellent in processing various types of engineering plastics

Plastics Materials: ABS, POM (Delrin), PC, PA6 (Nylon 6), PA66 (Nylon 66), PMMA (Acrylic), PP, PE, PVC, PS, HDPE, LDPE, PEEK, PEI (Ultem), PSU, PPS, PAI,

PPA, LCP, PTFE (Teflon), PVDF, PCTFE, PPSU, PI (Polyimide), FEP, PFA, ETFE

Composite Materials: Carbon Fiber Sheet, Carbon Fiber Tube, Prepreg Carbon Fiber, Woven Carbon Fiber, Fiberglass, G10, FR4, Glass Fabric Laminate

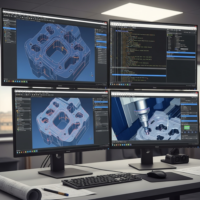

Why choose Protofirster for your 5-Axis CNC Machining Services Needs?

Our Advantages:

Fast Turnaround: 2 working days for urgent cases

MOQ 1pc: Feasible for prototype and low volume to meet your requirement at any stage.

High Precision: General tolerance is ±0.01mm; the best we can do is ±0.025mm.

Engineer Support: Our experienced engineer can help provide DFM to improve your design and save on the budget.

Secondary Finish: We provide anodizing, sandblasting, beadblasting, brushing, and many other processes of surface finish to perfect your design.

One-stop service to achieve centralization and efficiency of the supply chain

Start your free project evaluation and experience:

Your dedicated service consultant - tailor-made services

Easy to understand and communicate with us in a language you understand

Excellent quality and peace of mind - Expected results, guaranteed quality

All CAD files are secure and confidential.

![1754413553280798.png Get In touch [640x480].png](/uploads/ueditor/image/20250806/1754413553280798.png)